Is Your 358 Anti-Climb Fence Installation Truly Unbreachable?

Time:

2025-06-20

High security 358 anti climb fence installation isn't just about erecting panels – it's a precision engineering process where every bolt, clamp, and post depth determines the barrier's integrity. A single shortcut can transform a fortress into a liability. Understanding the critical nuances separates a compliant fence from an impenetrable perimeter.

Why 358 Mesh Demands Precision Installation

The "358" designation (3" x 0.5" mesh / 76.2mm x 12.7mm openings with ~4mm wire) creates an inherently formidable barrier. However, its security relies entirely on correct high security 358 anti climb fence installation:

Anti-Climb: Fingers/toes cannot grip the tiny apertures.

Anti-Cut: Robust 4mm wires welded at every intersection resist bolt cutters.

Rigidity: The dense mesh pattern forms a flat, unyielding surface.

Compromise the installation, and you compromise these core security features.

The 5 Critical Phases of High Security 358 Anti Climb Fence Installation

1.Site Preparation & Post Setting: The Foundation

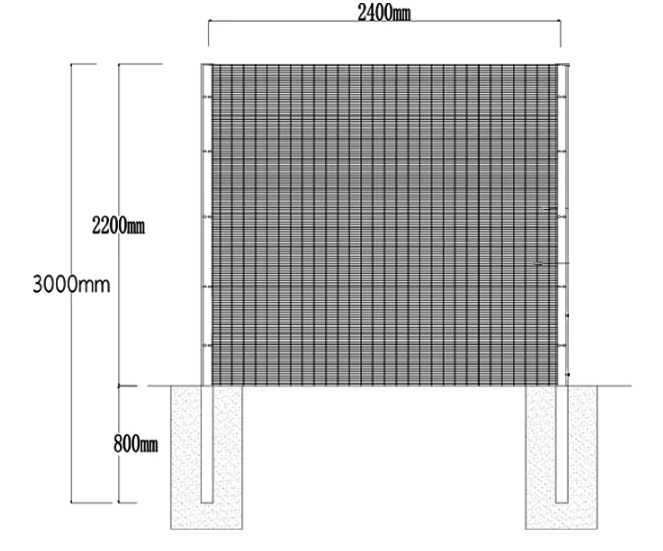

Post Hole Depth: Must exceed frost line depth and be 1/3 of total post height (e.g., 900mm hole for 2700mm post). Deeper for sandy soil or higher fences.

Post Spacing: Strictly adhere to panel width (typically 2.5m - 3.05m center-to-center). Wider spacing causes sagging – a critical weakness.

Post Alignment & Concrete: Posts set perfectly plumb in high-strength concrete (minimum 25MPa). Use temporary bracing until cured. Corner/end posts require larger foundations and bracing.

2.Panel Handling & Alignment: Zero Tolerance

Overlap Requirement: Panels must overlap posts by a minimum of 75mm on each side. This is non-negotiable for structural integrity and preventing panel separation under attack.

Vertical Alignment: Panels must be perfectly vertical. Use spirit levels constantly. Even minor leans create toe-holds or gaps.

Splicing: When multiple panels stack vertically for heights >~2.4m, horizontal splices must be continuous, robust, and tamper-proof.

3.Clamp Bar Fixation: The Security Lock

Clamp Bar Specs: Must match post dimensions (e.g., 60x5mm for 60mm post). Thinner bars bend, compromising tension.

Bolt Specification: High-tensile M8 bolts (minimum 8.8 grade) with anti-tamper nuts (e.g., Nyloc, crimped). Standard bolts shear or loosen.

Clamp Quantity: Follow engineering specs rigorously. Example for 2.4m panel on 60mm post: 9 clamps per internal post, 18 per corner post. Undersupplying creates weak points.

4.Tensioning & Final Integrity Checks

Uniform Tension: Panels must be drum-tight horizontally. Sagging reduces anti-climb effectiveness and eases cutting. Use specialized tensioning tools – never brute force.

Weld Inspection: Visually check every panel for missed or weak welds before installation. Reject defective panels.

Ground Clearance: Maintain ≤50mm clearance to prevent lifting or digging under. Concrete kickboards may be needed.

5.Toppings & Integration (If Applicable)

Razor Wire/Spikes: Secured via dedicated brackets above the fence line, not directly to mesh. Brackets must withstand significant upward force.

Electronic Systems: Ensure fence vibration sensors or E-Field systems are calibrated post-installation, as tension affects readings.

Essential 358 Fence Specifications Table

| Component | Critical Specification | Security Impact of Deviation |

|---|---|---|

| Mesh Wire | 4.0mm ± 0.1mm Diameter (8 Gauge) | Easier cutting, reduced rigidity |

| Welds | Full perimeter fusion at every intersection | Panels separate under stress |

| Zinc Coating | Min. 240 g/m² Hot-Dip Galvanized (HDG) | Premature rust = weakened wires |

| Powder Coat | Min. 80µm over HDG (RAL 6005 common) | Aesthetics + extra corrosion barrier |

| Posts (e.g., 3m fence) | 80x80x2.5mm SHS Galvanized Steel | Posts bend under load or impact |

| Clamp Bars | Thickness = 5-8mm (match post size) | Bars deform, loosening the mesh |

| Bolts | M8, Grade 8.8, Anti-Tamper Nuts | Bolts shear or are easily removed |

| Overlap | 75mm Minimum per side at every post | Panels detach, creating a breach point |

Material & Specification Failures That Compromise Installation

Even perfect technique fails with inferior materials:

✿ Substandard Galvanizing: Less than 240g/m² HDG rusts rapidly, weakening wires at ground level and welds.

✿ Thin Clamp Bars: Bend under tension, allowing panels to loosen.

✿ Low-Tensile Bolts: Shear under attempted forced entry.

✿ Undersized Posts: Buckle under load or impact. Post size must increase with fence height (e.g., 100x100x4mm for 4.2m+).

✿ Non-Anti-Tamper Nuts: Allows intruders to disassemble the fence silently.

Where High Security 358 Anti Climb Fence Installation Is Non-Negotiable

◆ Correctional Facilities: Prevents escapes and contraband entry. Requires highest specs + toppings.

◆ Critical Infrastructure (Power Plants, Utilities): Protects against sabotage and terrorism.

◆ Military & Government Sites: Safeguards sensitive assets and personnel.

◆ Airports & Ports: Secures perimeter against unauthorized access and smuggling.

◆ High-Value Industrial Sites: Deters theft and vandalism (pharma, data centers, manufacturing).

◆ Schools & Public Venues: Balances safety with visibility (often uses 3D curved profiles).

Frequently Asked Questions (FAQs)

Q: Why is the 75mm panel overlap at posts so critical in high security 358 anti climb fence installation?

A: This overlap ensures multiple clamps secure both panel edges directly to the post. Less overlap concentrates stress, risks panel pull-off, and creates a focal point for attack. It's fundamental to structural integrity.

Q: Can standard fence posts be used for a high security 358 anti climb fence installation? Absolutely not.

A: 358 mesh exerts high tension and wind load. Posts must be heavy-duty steel (SHS/RHS), sized and gauged for the fence height (e.g., 80x80x2.5mm min for 3m), set deep in concrete. Wood or lightweight metal posts fail.

Q: How does powder coating over galvanizing impact the high security 358 anti climb fence installation?

A: It doesn't change core installation steps, but the coating adds corrosion resistance and color. Ensure clamps/bolts are similarly coated to prevent bimetallic corrosion. Masking during coating must not obstruct weld points or clamp surfaces.

Q: Is DIY high security 358 anti climb fence installation feasible?

A: For true high-security applications, no. Precision alignment, tensioning, concrete work, and adherence to strict specs require specialized tools and expertise. Errors create vulnerabilities. Always use certified security fence installers.

Q: How often should a professionally installed 358 fence be inspected?

A: Bi-annually. Check for: loose clamps/bolts, corrosion (especially near ground), soil erosion around posts, panel tension, damage to coatings or mesh, integrity of toppings. Immediate repair is crucial.

Conclusion: Security is Built, Not Bolted On

✡ High security 358 anti climb fence installation is an engineered system. The mesh's inherent strength means nothing without:

✡ Precision Foundation: Correct post depth, size, spacing, and concrete.

✡ Flawless Execution: Rigorous 75mm overlap, perfect alignment, specified clamp/bolt quantities, uniform tension.

✡ Uncompromised Materials: Heavy galvanizing (240g/m²+), thick-gauge posts/clamps, high-tensile bolts.

✡ Professional Expertise: Certified installers understanding the security imperative.

Choosing a supplier and installer focused solely on cost guarantees failure. Demand proof of specification compliance and installation methodology. Your perimeter's integrity depends on it.

keyword:

76.2mm X 12.7mm Mesh Fence,Heavy Duty Fence Post Installation,Tamper Proof Fence Bolting,Perimeter Security Fence Standards

Share the