Why Choose Reinforced Structure Stainless Steel Wire Mesh for Industrial Filtration?

Time:

2025-06-20

Industrial processes demand filtration solutions that are robust, reliable, and long-lasting. When aggressive chemicals, high pressures, extreme temperatures, or abrasive particulates are involved, standard meshes often fall short. This is where Reinforced Structure Stainless Steel Wire Mesh becomes the essential component for efficient and durable industrial filtration.

Reinforced Structure Stainless Steel Wire Mesh is specifically engineered to provide superior mechanical strength and dimensional stability under demanding conditions. Unlike standard weaves, these meshes incorporate design features like thicker warp wires, crimping, multi-layer construction, or specialized weaving patterns to resist deformation, bulging, and premature failure. Combined with the inherent properties of stainless steel – exceptional corrosion resistance, high-temperature tolerance, and ease of cleaning – this creates an unparalleled filtration medium.

Key Advantages of Reinforced Structure Stainless Steel Wire Mesh

✔ Enhanced Durability & Longevity: The Reinforced Structure withstands high flow rates, pressure differentials (backwash, pulsing), and abrasive materials far better than standard weaves, significantly extending service life and reducing replacement frequency and costs.

✔ Superior Dimensional Stability: Resists stretching, sagging, and distortion, maintaining precise pore size and filtration accuracy over time, crucial for consistent product quality and process efficiency.

✔ High Strength-to-Weight Ratio: Provides exceptional structural integrity without excessive weight, important for large filter elements or applications where weight is a concern.

✔ Resistance to Mechanical Damage: Better withstands impact and handling during installation, cleaning, and maintenance.

✔ Maintains Filtration Precision: The stable structure ensures the specified micron rating remains consistent, preventing bypass of unwanted particles.

✔ Wide Chemical Compatibility: Stainless steel grades like 304, 316, and 316L offer excellent resistance to acids, alkalis, solvents, and corrosive environments common in chemical processing, pharmaceuticals, food & beverage, and petrochemicals.

✔ High-Temperature Performance: Maintains integrity and strength at elevated temperatures unsuitable for polymer-based filters.

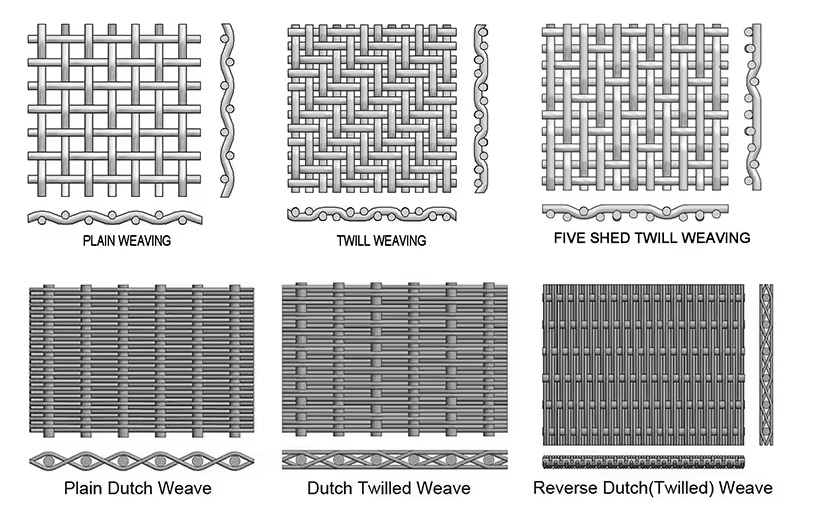

Common Types of Reinforced Structure Stainless Steel Wire Mesh for Filtration

▶ Dutch Woven Mesh (Plain Dutch, Twilled Dutch)

This type features a dense weave with relatively thick warp wires and much finer, tightly packed weft (shute) wires. This creates a robust, smooth filtering surface with very fine filtration capabilities (down to 1 micron or less). The "Reinforced Structure" comes from the thick warp wires providing the primary strength, making it ideal for high-pressure liquid filtration and clarifying applications. Filtration ratings are typically defined by the mesh count and wire diameters.

▶ Multi-Layer (Duplex & Triplex) Woven Mesh

These meshes consist of two or three distinct layers sintered or tightly woven together. Often, a fine filtering layer is sandwiched between coarser, stronger support layers. This "Reinforced Structure" provides the strength needed for high-pressure applications while achieving very fine filtration. They are widely used in hydraulic systems, fuel filtration, and critical process filtration where both fine particle retention and high burst strength are mandatory.

▶ Five-Heddle (5-Heddle) Weave Mesh

Woven using a complex five-shaft loom process, this mesh has a smooth, almost solid surface on one side and a distinct pattern on the other. This unique "Reinforced Structure" offers excellent flow characteristics, high particle retention capacity, and good strength. It's particularly valued as the base material for corrugated (knitted) wire mesh packing used in distillation and separation columns, where its strength and surface properties are critical.

▶ Crimped Woven Wire Mesh (Lock Crimp, Intercrimp)

Before weaving, the wires are pre-crimped (deformed) at precise intervals. When woven, these crimps lock the wires firmly at their intersections. This mechanical locking creates an extremely rigid and stable "Reinforced Structure" highly resistant to movement under load or vibration. It's ideal for heavy-duty screening, scalping, grizzly screens, and filtration elements requiring maximum structural integrity. Available in various crimp styles and wire thicknesses.

Comparison of Key Reinforced Mesh Types:

| Feature | Dutch Woven | Multi-Layer (Duplex/Triplex) | Five-Heddle | Crimped Woven |

|---|---|---|---|---|

| Primary Reinforcement | Thick Warp Wires | Multiple Sintered/Woven Layers | Complex Weave Pattern | Pre-Crimped Wires |

| Fineness (Microns) | 1μm - 100μm+ | 5μm - 200μm+ | 20μm - 500μm+ | 100μm - 10,000μm+ |

| Key Strength | High Pressure Resistance | High Burst Strength | Flow & Surface Stability | Maximum Rigidity & Vibration Resistance |

| Typical Uses | Fine Liquid Clarification, High-Pressure Filters | Hydraulics, Fuel, Critical Process | Corrugated Packing, General Filtration | Screening, Scalping, Heavy-Duty Filters |

Deep Processed Products Utilizing Reinforced Mesh

The Reinforced Structure Stainless Steel Wire Mesh forms the foundation for critical filtration components:

☞ Filter Baskets & Strainers: Fabricated into cylindrical, conical, or basket shapes for pipeline strainers (Y-strainers, basket strainers), suction filters, and in-tank filtration.

☞ Filter Cartridges & Elements: Rolled, pleated, or welded into cylindrical cartridges for housing-based filtration systems in various industries.

☞ Filter Press Plates & Screens: Used in recessed chamber or membrane filter presses for sludge dewatering and cake filtration.

☞ Demister Pads & Vane Packs: Employed to separate liquid droplets from gas/vapor streams in scrubbers, knock-out drums, and distillation columns.

☞ Corrugated (Knitted) Gauze Packing: Made primarily from Five-Heddle mesh, used for mass transfer in distillation and absorption towers.

Why Material Grade Matters

The choice of stainless steel grade is integral to the performance of the Reinforced Structure:

★ AISI 304 (1.4301): Excellent general-purpose corrosion resistance, good formability, widely used in food, chemical, and environmental applications.

★ AISI 316 (1.4401 / 1.4436): Superior corrosion resistance due to Molybdenum (Mo) content, essential for marine environments, chlorides, acids, and pharmaceutical processing. 316L (Low Carbon) is preferred for welded components to prevent sensitization.

★ Special Alloys (904L, Hastelloy, etc.): Used for exceptionally aggressive chemical environments or extreme temperatures.

Frequently Asked Questions (FAQs)

Q: What makes "Reinforced Structure" mesh different from standard woven mesh?

A: Standard plain weave mesh uses wires of similar diameter woven over and under each other. "Reinforced Structure" meshes incorporate design elements like significantly thicker wires in one direction (Dutch), mechanical locking via crimps, multiple bonded layers, or complex weaves (5-Heddle). These features dramatically increase strength, rigidity, and resistance to deformation under pressure, flow, or abrasion compared to standard weaves.

Q: Can Reinforced Structure Stainless Steel Wire Mesh handle high temperatures?

A: Absolutely. Stainless steel grades like 304 and 316 retain their strength and corrosion resistance at much higher temperatures than polymer filters. The specific continuous operating temperature depends on the grade (e.g., 304 up to ~870°C / 1600°F, 316 up to ~800°C / 1470°F in intermittent service). The "Reinforced Structure" ensures the mesh maintains its dimensional stability under thermal cycling.

Q: Is this type of mesh suitable for corrosive chemical filtration?

A: Yes, this is a primary strength. Grades like 316/L stainless steel offer excellent resistance to a wide range of acids, alkalis, and solvents. The "Reinforced Structure" ensures the mesh integrity is maintained even when exposed to corrosive media under pressure. For extremely aggressive chemicals, specialized alloys are available.

Q: How fine can Reinforced Stainless Steel Mesh filter?

A: Dutch woven meshes offer the finest filtration, capable of retaining particles down to 1 micron or even sub-micron levels with specific weaves. Multi-layer meshes can also achieve fine filtration (5-20μm) with high strength. Five-heddle and crimped meshes are generally used for coarser filtration tasks.

Q: Is it cost-effective compared to disposable filter media?

A: While the initial cost is higher than disposable media (paper, polymer), "Reinforced Structure Stainless Steel Wire Mesh" is extremely durable and reusable. It can be cleaned repeatedly (backflush, ultrasonic, chemical) and lasts for years or even decades with proper care. This eliminates ongoing media replacement costs, reduces downtime for change-outs, and minimizes waste, leading to significant long-term savings and operational efficiency.

keyword:

Chemical Filtration Mesh,Filter Basket Material,Wire Mesh Filter Elements,Industrial Screen Mesh

Share the