Innovative Uses of Steel Grating in Modern Infrastructure

Time:

2025-04-30

Steel grating is a versatile, high-strength material widely recognized for its durability and adaptability across industries. This article explores its diverse applications, technical specifications, and industry-specific benefits.

Key Steel Grating Types & Structural Advantages

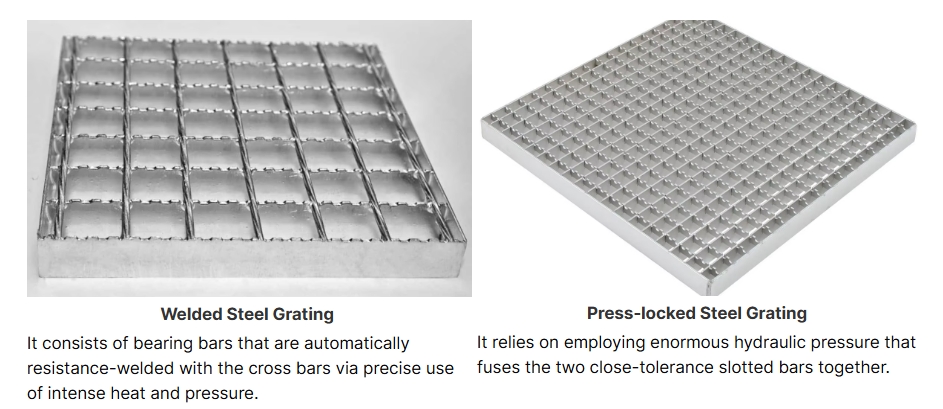

1. Welded Steel Grating

Structure: Bearing bars welded perpendicular to cross bars under high pressure.

Applications: Industrial platforms, stair treads, mezzanines.

Benefits: Superior load-bearing capacity (ideal for heavy machinery areas).

2. Press-Locked Grating

Structure: Cross bars mechanically locked into grooved bearing bars.

Applications: Walkways, bridges, architectural facades.

Benefits: Smooth surface, anti-slip properties.

3. Heavy-Duty Dense Grating

Structure: Tightly spaced bars (e.g., 30/100 series with 30mm bearing bar pitch).

Applications: Oil refineries, chemical plants.

Benefits: Resists impact and corrosive substances.

4. Composite Steel Grating

Structure: Combines steel grating with checkered plates (e.g., 3mm-thick sealing layer).

Applications: Mining conveyor platforms, wastewater treatment plants.

Benefits: Prevents debris fall-through while maintaining airflow.

Industry-Specific Applications

1. Petrochemical & Energy Sector

Use Case: Offshore oil rig platforms (G323/60/100 series).

Why Steel Grating?: Withstands harsh chemicals, saltwater corrosion (hot-dip galvanized coating).

2. Urban Infrastructure

Use Case: Pedestrian bridges, subway station ceilings (40/50 series).

Why Steel Grating?: Lightweight yet durable, reduces construction costs.

3. Agriculture & Aquaculture

Use Case: Poultry house flooring, fish farm walkways (30/50 series).

Why Steel Grating?: Easy waste drainage, ventilation, and predator-proofing.

4. Coastal & Marine Engineering

Use Case: Port dock surfaces, shipyard gangways.

Why Steel Grating?: Galvanized finishes extend service life to 95+ years in saline environments (see the following Table).

Technical Specifications & Best Practices

Sizing Guidelines

| Parameter | Standard Dimensions |

|---|---|

| Bearing Bar Pitch | 30mm, 40mm, 60mm, 100mm |

| Cross Bar Pitch | 50mm, 100mm, 200mm |

| Panel Width | 1m (customizable up to 1.2m) |

| Thickness | 3mm, 5mm, 8mm, 10mm |

Lifespan Optimization

Hot-Dip Galvanizing: Increases longevity by 3–5× vs. untreated steel.

Environment-Specific Choices:

Industrial Zones: 60+ years (40/100 series).

Coastal Areas: 95+ years (30/100 series with 12mm thickness).

Design Considerations

Load Requirements:

Use 30/100 series for truck-loading docks (≥5-ton capacity).

Opt for 40/50 series in pedestrian zones.

Span Support:

For spans >1.5m, add mid-frame supports to prevent deflection.

Safety Compliance:

Serrated surfaces (e.g., 8×8mm mesh) for wet environments.

Future Trends in Steel Grating

Sustainable Materials: Recycled steel gratings with powder-coated finishes.

Smart Integration: Sensor-equipped gratings for structural health monitoring.

keyword:

Steel grating applications,Industrial steel grating specifications,Hot-dip galvanized grating lifespan,Press-locked vs. welded grating,Composite steel grating design

Share the