Bar Grating Measurement Guide: Precision Sizing for Industrial Applications

Time:

2025-05-28

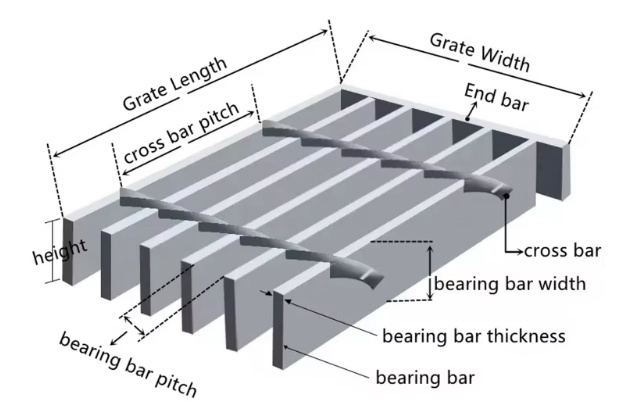

Accurate bar grating measurements ensure structural integrity, safety, and cost efficiency. Follow this technical guide to specify dimensions correctly for steel, aluminum, stainless steel, or fiberglass grating.

Critical Dimensions to Specify

1. Material & Construction

☸ Steel: Welded, Press-Locked, Riveted, Swage-Locked

☸ Aluminum: Swaged-Locked, Flush Top

☸ Stainless Steel: Welded, Swage-Locked

☸ Fiberglass: Pultruded, Molded

2. Surface & Finish

Options: Smooth, Serrated, Slip-Resistant

Finishes:

◆ Steel: Galvanized, Painted, Mill

◆ Aluminum: Mill

◆ Stainless Steel: Mill, Sandblasted

3. Structural Specifications

Bearing Bar Spacing: 1-3/16" to 4" (30mm–100mm)

Span: Unsupported length (critical for load capacity)

Panel Width & Length: Tolerance ±0.25"

Bearing Bar Depth: 1"–6" (25mm–150mm)

Thickness: 3/16"–1" (5mm–25mm)

4. Anchoring System

Welded | Saddle Clips | G-Clips | Grategrip Fasteners | Weld Lugs | Z-Clips

Step-by-Step Measurement Process

1. Identify Application Requirements

✿ Load capacity (e.g., ANSI/NAAMM MBG 531 standards)

✿ Environment: Corrosive, high-traffic, or extreme temperatures

2. Measure Physical Space

✿ Span: Distance between support structures.

✿ Clear Opening: Deduct 0.5" for anchor clearance.

3. Verify Bar Orientation

Bearing bars perpendicular to supports for maximum strength.

4. Cross-Check Tolerances

Use calipers for bar thickness/depth precision.

📐 Pro Tip: Submit a sketch with dimensions to suppliers to eliminate errors.

FAQs: Bar Grating Measurement

Q1: How do I calculate load capacity for grating?

A: Provide span, bearing bar spacing/depth, and material. Suppliers use formulas based on I-weight (moment of inertia).

Q2: Can I cut steel grating onsite to fit irregular spaces?

A: Yes—but specify "uncut" in orders. Field-cutting requires abrasive saws and edge sealing (for galvanized steel).

Q3: What if my measurements are between standard sizes?

A: Order oversized and trim, or request custom fabrication (minimal cost premium).

Q4: How does serrated vs. smooth surface impact dimensions?

A: Serrations add 0.06"–0.12" height; factor this into clearance requirements.

Q5: Why specify anchor type early?

A: Clips/lugs affect panel sizing (e.g., weld lugs add 2" to total width).*

Need Exact Specs?

➡️ Share your application (walkway, trench cover, platform) and load requirements. We’ll provide:

♛ CAD drawings

♛ Load tables

♛ Material recommendations

Contact Us for a measurement template!

keyword:

Bar grating sizing guide,Steel grating specifications,Grating span calculation,Grating anchor systems,Swage-locked grating dimensions,Serrated grating thickness

Share the